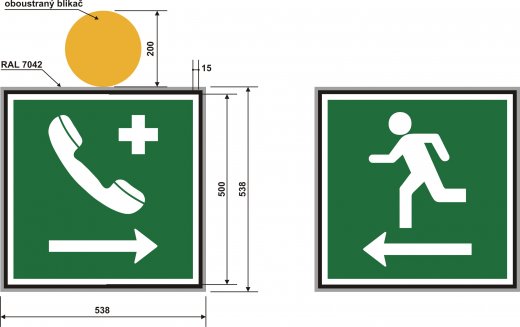

Illuminated and retroreflex traffic signs

Sign box is made of stainless steel EN 1.4404 standard with IP cover IP 65. Surface treatment of the box is powder firing paint. The active surface of the sign consists of a non-reflex, translucent foil /C 14a/. Another command /turn off the engine/ or microprismatic retroreflex translucent foil /Escape exit marking/. The lighting system is made of fluorescent tubes with a ballast. The brightness ratio, the brightness and colors of the active surface the requirements of CSN EN 12899-1 and its National Annex.

Retroflex signs

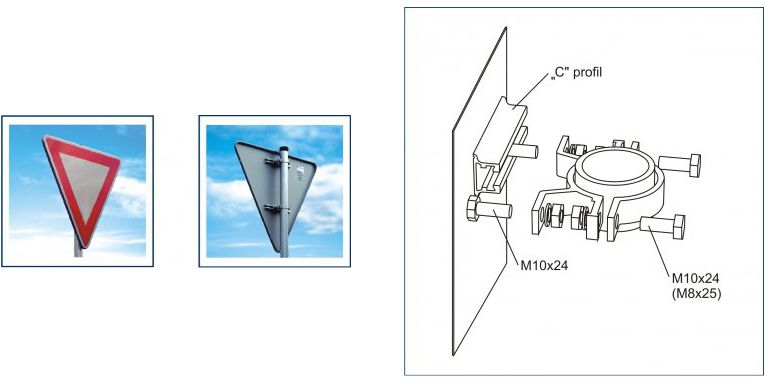

Type L – shield with molded edge

Shield of the sign and active area are made in accordance with requirements of ČSN EN 12899-1 in line with the individual quality classes and requirements listed in the National Annexe, accuracy of symbols corresponds to VL 6.1. Production is controlled in accordance with ČSN EN 12899-4 Requirements for factory production control. Our laboratory is equipped with measuring devices for measuring retroflection, chromatic coordinates and brightness factor. The surface protection /thickness of the layer/ is regularly checked for individual sign shields with a measuring device.

The sign shield is made using the technology of double bending of the edge by pressing sheet metal with zinc protection. The double edge of the perimeter of the sign ensures high resistance of the sign shield against external forces, especially vandals. A steel profile is attached on the back side using welding screws to fasten the screws of the sleeves. This enables easy fitting of the sleeve without braeking the front surface and high strength of the connection.

View of the front and back of the C-profile sign shield Detail of mounting the sleeve to the sign shield with C-profile

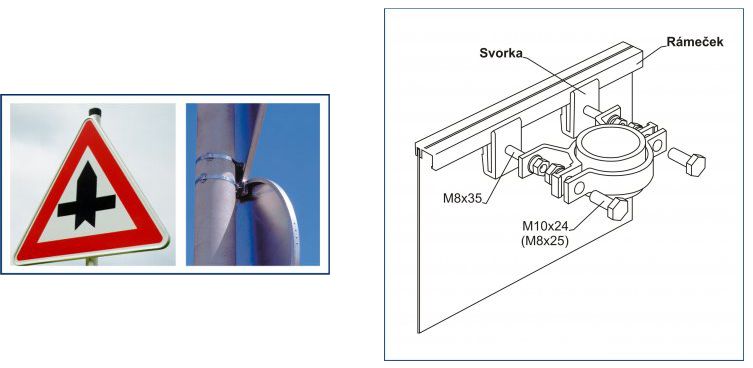

Type R – signs with reinforced frame

Sign shield consists of a steel sheet with zinc protection and a perimeter frame made of drawn aluminium profile. The perimeter frame ensures high resistance of the sign shield against external forces, especially vandals. An aluminium profile is attached to the rear side of the shield using welding screws C to fix the screws of the sleeves or the sleeve can be attached directly to the frame with clamps.

View of the back and front of the sign reinforced with a frame Detail of mounting the sleeve to the perimeter frame of the sign shield

Type LM – mechanically changeable traffic signs

Sign shield is made by the technology of double bending of edge by pressing sheet metal with zinc protection. By mechanically turning the additional part of the sign shield, the meaning of the traffic sign symbol can be changed /max. 2 symbols/. The use of this design of road signs is suitable for places without electricity supply where the symbol is changed at long intervals, or whose use is short-term /e.g. police checks at highway rest areas/. Securing the individual positions of the additional shield is done with a plastic rotary lock.

Large area traffic signs

Large-scale traffic signs are signs with a total area over 1,5 m2. Each large-scale traffic sign is designed individually in terms of graphic requirements. The pasting of retroreflex foils is carried out in the application presses which guarantee the creation of a basic surface, without air bubbles and damage to the foil. The application of symbols is carried out by workers on the basis of detailed workshop documentation. The resulting road sign passes the double quality check of accuracy and production correctness.

Type LA – from aluminium segments

Due to its low weight, the construction is chosen for road signs placed above the road, especially portal constructions. The core is a drawn aluminium profile with a width of 215 mm with a longitudinal groove for attaching screws and locks. With the help of these locks, the supporting part of the road sign is attached to the vertical beams of the portal. For greater safety of an entire structure, the lower segments are anchored to the distribution beams with a direct screw connection which prevents the risk of lower segments becoming loose in the lock.

Detail of the attachement of segments to the portal beam Large-scale signs type LA on the Prague ring road

Type LF – from segments of galvanized sheet

The basis of a construction is a bent sheet metal profile with a width of 215 mm with edge hems in the shape of lock, which prevent the penetration of light into the front surface and ensure mutual static cohesion between individual adjacent profiles. The individual profiles of the front bearing shield are attached to each other by connectors to which a sleeve or clip is attached with a screw or clip depending on type of stand used.

Detail of fixing the segments to the stand Segment construction with attachement to the lattice stand Motorway D8

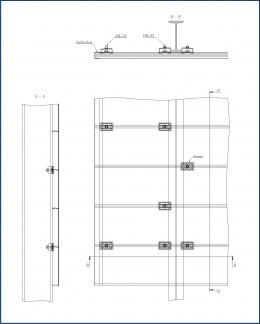

Type VPL 1 – road sign made of galvanized sheet panels

This structural system consists of sheet metal panels with a surface protection of high resistant aluzinc. The width of panels is 590 mm and the additional modules are 220 mm wide. The use of individual additional modules determines the required height of large-scale sign. For higher rigidity of individual panels,vertical reinforcements are used, the edges of the shield are neaten by edging around the entire perimeter. The main advantages include the high-quality and integral appearance of the front area, as well as rigidity. The structure is easily transportable in its disassambled state, its assambly, after training by our technicians, can be carried out by the customer´s assembly company.

These supporting structures have a high resistance to theft due to the rigid connection of individual parts and the difficulty of being transported by manual handling carts.

Type VPL 1 – view of the foundation construction Graphics of the symbol in the width of division of segment A view of the back of the segments and its connection to the structure

Send your questions to info@znacky-praha.cz

Copyrights © 2025 Značky Praha s.r.o.