Traffic sign design and control

The quality of the project is a prerequisite for its successful implementation in practice. That is why we wanted to project our practical experience into the construction preparatory phase. A detailed design of traffic signage drawn up according to the latest standards, experience and trends in the field, and an accurate list of works are a necessary basis for the investor, contractor and manufacturer.

Our company Značky Praha s.r.o. provides services at a high professional level in the field of:

- Traffic signage projects processing

- Processing projects of traffic information systems for the orientation of road users

- Processing projects of traffic engineering measures to ensure the implementation of road constructions

- Providing support services related to the negotiations with state authorities

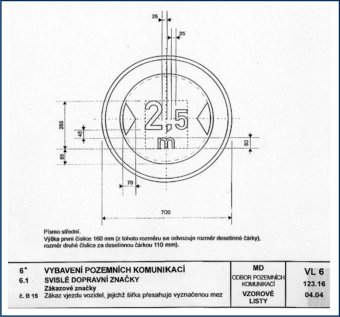

Drawings of large-scale traffic signs

We proceed to the processing of drawings of large-scale signs with the knowledge that a large –scale sign is an expensive product and possibility of later changes is limited. We therefore pay an increased attention to the preparation of drawing documentation for the production of large-scale sign. The drawings are made according to the template supplied by the customer.

The drawing of large-scale sign can be split into several stages:

- Proposal

- Client´s approval

- Release of approved drawings into production

In case of a large-scale sign, the quality of the template has a direct impact on the quality of the sign itself. The draft proposal is usually the approved project documentation. In the optimal case, the project is processed according to valid standards and regulations and discussed and agreed with the competent authorities. The drawings of large-scale signs are made in detail according to the regulation PPK – ZNA. Requirements for the implementation and scope of the traffic sign project in individual stages of documentation on highways and expressways in the administration of the Directorate of Roads and Highways of the Czech Republic.

However, in practical life, it is often different. It happens that sign drawings are not drawn in accordance with the standards /incorrect dimensions of symbols and fonts, mutual distances in elements in graphics, font type and color design of targets or their content shows deficiencies at the first glance /wrong or missing destinations, road numbers etc/. All this can result in the dimensions of the sign being distorted in the project and details of the sign being incomplete or misleading. The manufacturer then has little possibiliy to remove errors. Most of the time, only the most glarig flaws in the layout of the graphics can be removed. It is not possible to change content of the signs /destinations, road numbers/, this would mean reworking the project.

Large-scale sign design

Before processing the drawing of the sign, it is important to determine the input data for the desing:

- Objectives

- Order of objectives

- Color design of the sign and objectives

- Road numbers

- Other symbols /design of arrows, input of traffic sign symbols etc./

- Font height and symbol dimention

- Type of retroreflex foil

The conditions may change depending on the type of communication, where the sign is fitted. Exact requirements are determined by applicable regulations and standards /laws, decrees, standards, technical conditions and data sheets/. If it does not conflict with regulations and standards. It is advisable to take into account the design of signage around intended location of the sign.

The design of the sign is then carried out according to the sample sheets VL 6.1 Vertical traffic signs.

Production of a large-scale sign

The sign is produced in accordance with the drawings approved by the customer. During production, an independent check of product compliance with drawing documentation and CSN EN 12899-1 is carried out. In addition to the light-technical properties of the film geometric accuracy is checked.

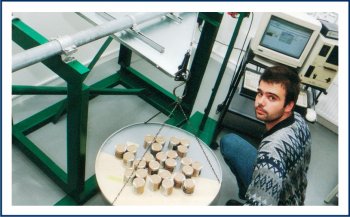

Quality control

To ensure high quality of our products, the control and development laboratory was built in our company. Here, quality control is carried out from the input materials of individual subcontractors to the control of the final product. Proper records of individual procedures are kept in protocols, including sampling from individual production batches. These are established and archived for the lifetime of the product , care is also taken to properly calibrate our measuring devices at manufcurer´s place or accredited institutes.

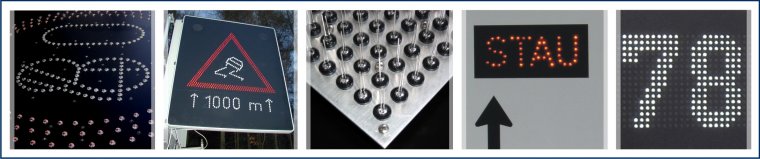

Permanent and mechanically variable traffic signs

- Checking the active area of the sign

- Metering colorimetric coordinates

- Retroflex metering

- Grid test

- Measuring the accuracy of symbols

- Checking the quality of the sign shield

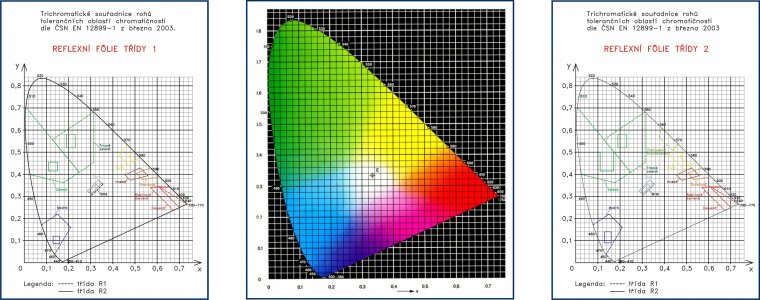

Metering colorimetric coordinates

The metering of colorimetric coordinates is an important control procedure in production, which should ensure good visibility of the traffic sign symbol during its lifetime. This requirement is also included in the standard EN128989-4 – Factory production control.

Metering of colorimetric coordinates is an important control procedure in production which should ensure good visibility of the traffic sign symbol during its lifetime. This requirement is also included in the standard EN12899-4 Production management in the factory. Every manufacturer works with colors in the screen printing symbol production technology, which can negatively affect the overall resultl with incorrect technological procedures (improper mixing of pigment components of the paint, wrong dose of primer components such as solvent and retarder). For this property the CSN EN12899-1 standard defines two basic areas in the colors chart. Class R2 which is narrower and stricter band of color determination but if a new product is in this area, it is likely that its life on the road will be higher than a product that is in the less strict class R1. Use of these classes for individual types of traffic types (according to meaning) is determined by the national annex CSN EN 12899-1, but in general the rule applies that road signs corresponding to class R2 when new, will have a longer lifespan.

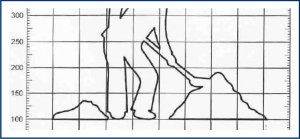

Retroflection measurement

The measurement of the retroflection is expecially necessary to verify the visibility of road signs in the dark, when the visibility of the signs is ensured by reflection of the vehicules´ lights from the retroflective film. Therefore, it is necessary to verify that the new product meets the standard paramaeters. The light-technical properties of the film should then be randomly checked on site throughout the product´s lifetime. Requirements for retroflection value are devided by value into classes R´1 (Engineering Grade), F´2 (High Intensity) and R´3 (Diamond Grade).

Cross Cut Test

The test shows us the quality of adhesion of the paint to the surface of the retroflective foil construction. The test is carried out in our quality system as an orientation to assess the quality and durability of the applied paint. If the paint is not properly connected to the surface of the material, environmental influences /acid rain, maintenance of the front surface and others/ can also lead to its premature desruption which results in deterioration of the visibility parameters in daylight. If, for these reasons, the value of colorimetric coordinates deviates from the R 1 parameters, the product is apparently not usable and must be prematurely replaced wih a new one.

Measuring the accuracy of a symbol

The procedure is part of control of the accuracy of the foils application of the frontal surface and is carried out on the basis of the product´s workshop documentation. With screen printing technology, the accuracy of the symbol on the screens and edges of the foil are checked. For signs produced by such technology, workshop documentation is released for each sign on the basis of which quality control measures the symbols.

Sign Shield Quality Control

We measure compliance with the mechanical resistance of the sign shield on a load bench continuously from individual metal sheets deliveries. We check the quality of the welds and the tightening of the self-locking nuts of the profiles for attaching the sleeves. The tightening of the nuts is checked using the torque wrench that is calibrated to a specified gauge.

Measurement of luminous properties of LED signs

Send your questions to info@znacky-praha.cz

Copyrights © 2025 Značky Praha s.r.o.