Traffic signs

Retrofeflective and illuminated traffic signs

STANDARD-SIZED TRAFFIC SIGNS

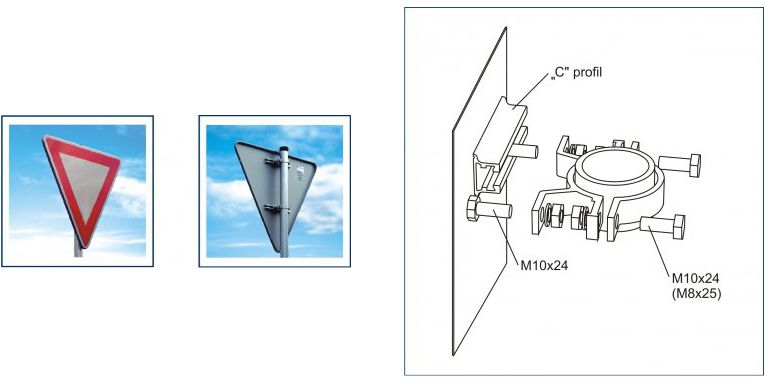

TYPE L – SIGNS WITH PRESSED EDGES

This sign and its active face are manufactured in accordance with the requirements of norm ČSN EN 12899-1 according to the individual quality class, as well as with the requirements listed in the norm's national supplement. The exactness of the symbols complies with VL 6.1. Production is monitored in accordance with EN 12899-4 Factory Production Control. Our laboratory is equipped with measurement devices for measuring retroflection, chromatic coordinates, and brightness agents. The surface protection (thickness of the layer) is regularly checked for individual signs with measuring instruments. More on these procedures and individual measurements can be read in the "Quality Control" section.

The sign is manufactured with double-edge technology, implemented by pressing sheet metal with zinc surface protection. The sign's double-edged perimeter ensures strong durability against external forces, particularly vandals. A steel support bar is attached to the reverse side with the help of welding screws in order to fortify the screws of the clamp. This allows the clamp to be easily set without disrupting the front surface and the security of the joint.

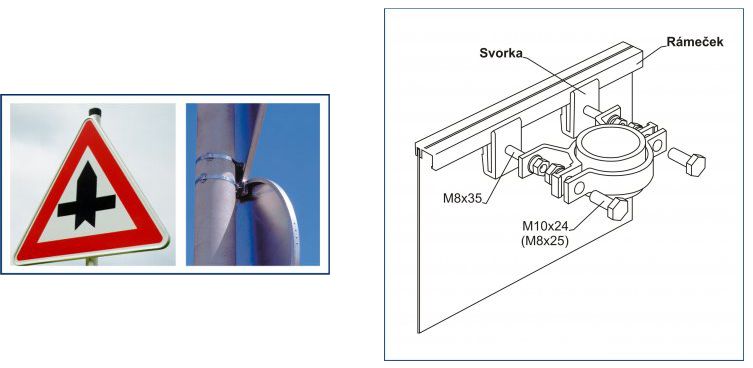

TYPE R – FRAME-REINFORCED SIGNS

This sign is made of a steel sheet galvanised with a zinc protection layer and an aluminium frame. The frame ensures strong durability against outside forces, particularly vandals.

An aluminium C bracket attached to the back of the sign with the help of welding screws anchors the clamp screws, or it is possible to attach the clamp with the help of clips directly on the frame.

TYPE LM – MANUALLY ADJUSTABLE TRAFFIC SIGNS

This sign is manufactured with double-edge technology, implemented by pressing sheet metal with a layer of zinc. By manually turning the additional piece on the sign one can change the traffic sign symbol (max. 2 symbols). This type of sign is well-suited for areas without access to electricity where the symbols only require changing after long intervals, or where they are used in the short-term (e.g. police inspections at highway rest stops). A plastic swivelling lock secures the individual positions of the additional sign.

LARGE-SCALE TRAFFIC SIGNS

Large-scale traffic signs have a total area over 1.5 square metres. The graphics of every large-scale traffic sign are designed individually. The requirements for size and carrying capacity of the construction's surface are based on this design. The application of the retroflective film is carried out on rollers, which ensures the creation of a base surface without creating air bubbles or damaging the film. Workers apply the symbols based on detailed documentation, and the resulting traffic sign goes through a two-stage test of precision and accuracy.

The following basic construction types can be found in our product line based on use and shape:

TYPE LA – TRAFFIC SIGN FROM ALUMINIUM SLATS

This light-weight design is used for traffic signs located above the roadway, particularly on portal constructions. Its base is a section of aluminium 215 mm wide with a horizontal groove for catching the screws and locks. With the help of these locks the load-bearing part of the sign is anchored to vertical beams on the overhead scaffolding. For greater safety the bottom slats are anchored to the beams with a directly screwed joint, which protects against the danger of the bottom slats coming loose.

TYPE LF – TRAFFIC SIGN FROM GALVANISED STEEL SLATS

The base of this design is a curved section of aluminium 215 mm wide with seams along the edge, which form a lock that prevents light from penetrating through to the front side and ensures static cohesion between the individual neighbouring sections. The individual sections of the sign face are held together by connectors, to which a brace or a clip is screwed, depending on the type of stand used.

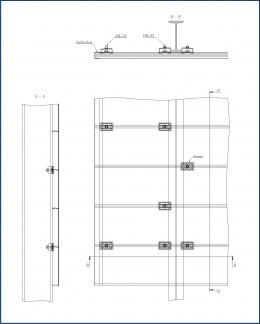

TYPE VPL1 – TRAFFIC SIGN FROM GALVANISED STEEL PANELS

This design consists of panels of sheet metal protected with a layer of highly resistant Aluzinc. The width of the panels is 590 mm, with supplementary modules 220 mm wide. The use of individual supplementary modules is determined by the required height of the large-scale sign. Vertical reinforcements are used to solidify individual panels, and the edges of the sign are smoothed out by the application edging around the whole perimeter. Among the main priorities are the high-quality and coherent appearance of the face, as well as stability. The design is easily transportable when unassembled, and assembly can be done by the customer's assembly company following instruction by our technicians.

These support structures are highly resistant to theft due to the firm connection of their individual parts and the difficulty of transporting them in hand-carts.

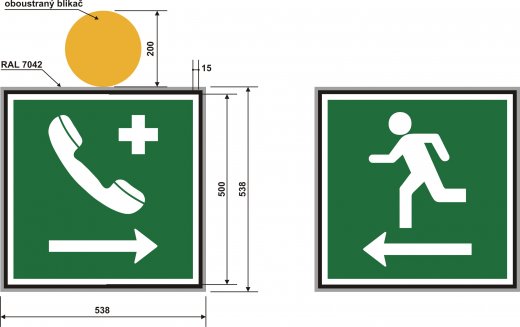

TYPE SDZ – ILLUMINATED SIGNS

This sign's box is manufactured from EN 1.4404 stainless steel with IP 65 protection. The box's surface is treated with a powder coating. The sign's active surface consists of a non-retroreflective translucent film (C 14a – Other message (Turn off motor)) or microprismatic retroflective translucent film (Emergency exit sign). The lighting system comprises fluorescent tubes with a stabiliser. The proportion of brightness agents, the overall brightness, and colour of the active surface meet the requirements of ČSN EN 12899-1 and its national supplement.

VARIABLE TRAFFIC SIGNS

Variable message traffic signs are used to manage and direct roadway traffic. With the help of traffic information equipment, we can provide drivers with up-to-date information about the vacancy levels of parking lots, roadway temperature, traffic situations, etc.

Different types of displays are best-suited for different situations and conditions. The type of technology chosen should be optimal for the given roadway and conditions (vehicle speed, visibility, type of information).

Variable traffic signs and devices for providing traffic information must fulfil regulations EN 12966-1 Variable Vertical Traffic Signs and TP 141 Fundamentals for Variable Traffic Marking Systems and Road Traffic Information Displays.

PRISMATIC TRAFFIC SIGNS

This system is based on a mechanically changing active surface, which is made of three-sided prisms. Each prism is powered by its own step motor with a position reader, driven by a central electronic system. The position of individual prisms is continuously checked, thus in the case of outside interference the affected prism automatically returns to the correct position after being unblocked. If the front face is set to the right position, the inspection output is activated. The prisms are stopped in a static position via the 'static moment' of the step motor.

Control of the central unit of the variable traffic sign is possible in the series line RS 485, RS 232, or through various modifications of the parallel interface. Variable traffic signs generally draw their power from the standard TN-S 230 V/50 Hz grid; if necessary, it is possible to add a back-up source with automatic recharging. Aside from the classic cable connection, the connection between the sign's control system and the traffic control centre can be done through various wireless transmissions, including the GSM mobile transfer system.

LCD

This technology is used for its readability from wide angles, mainly in urban areas for traffic information displays (TID), for example on parking systems. The type of display and number of segments are chosen based on the required level of readability and type of information. For basic digital systems, 38 segments are used. The shape of the characters is determined by the shape of the segments on the display's glass.

LED

The symbols on these traffic signs are created by individual points of light comprising an LED, an optic lens, and a rubber seal. The individual points of light are formed into the shape of the desired symbols in such a way as to come as close as possible to regulation VL 6.1. The sign face on which the optical lenses are planted has a highly dull colour that together with the optical qualities of the lens prevent any unwanted effects from the reflection of the sun (class R 2). Based on the type of optical system used, we offer these signs with angles of light ray radiation (in accordance with EN 12966-1) in classes B 1, B 3, and B 5. The colours of the individual lights correspond to class C 2, and inspection of individual parts in terms of colour and brightness is carried out in our laboratories in production batches in accordance with regulation EN 12966-2 Factory Production Control.

TID

TID is made up of light points located on a matrix display. The distance between individual dots is set at a maximum of 22 mm, which ensures quality portrayal of the lettering in accordance with DIN 1451. It is possible to choose the length of the lettering and the height of the rows as well as the use of uppercase or lowercase lettering, as needed. Each point of light is controlled individually and watched over by a central unit. The optical system is the same as for the variable traffic signs; the angle of light ray radiation is B3 (see ČSN EN 12966-1). Brightness is continuously managed in 256 degrees based on the environmental lighting data from the sensor or central management system.

Any queries info@znacky-praha.cz

Copyrights © 2025 Značky Praha s.r.o.